RESEARCH AND DEVELOPMENT

HANKUK Precision is leading the advanced mold

technology by applying a prediction

system necessary for high quality,

short delivery period,

and low-cost mold manufacturing

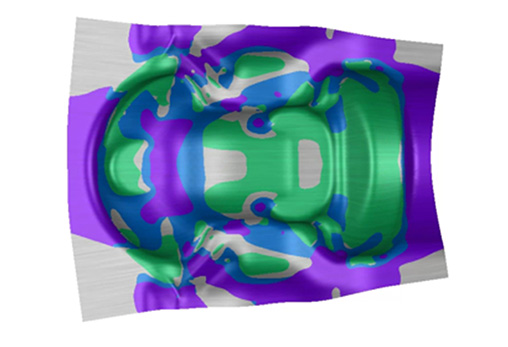

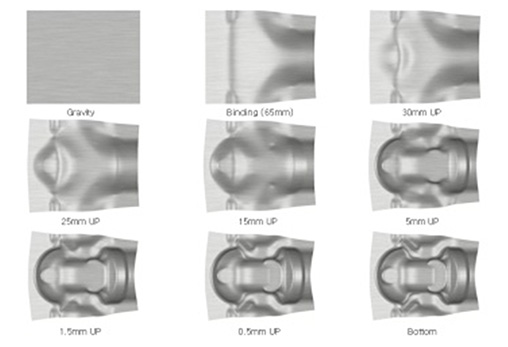

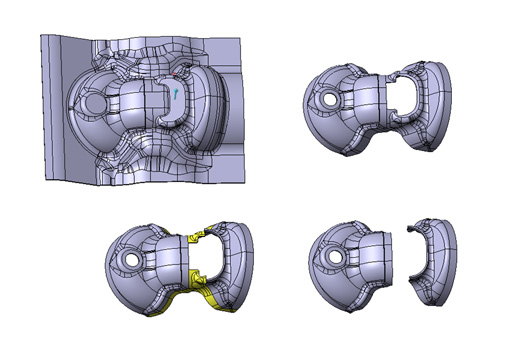

AutoForm Molding Analysis

AutoForm is responsible for digitally planning and verifying thin plate molding processes and products. In addition, it plays a role in early detection of molding problems and optimizing blanking and trim lines through the process simulation.

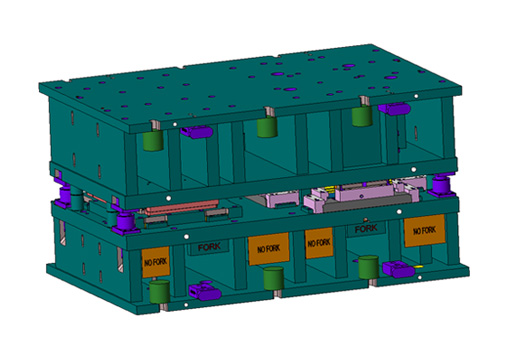

SIMENS NX 3D Mold Diagram Formulation

SIMENS NX offers a design and simulation manufacturing solution that quickly and efficiently supports the creation of 3D molds.

Process-Specific Data Creation for CATIA 3D Geometry

CATIA leverages product 3D modeling simulation capabilities to deliver optimal efficiency by incorporating all of the user’s demands.

Technology Research

and Development Department Procedures

HANKUK Precision introduces the R&D procedure in which even the smallest detail, each and every components are examined, and detailed efforts are incorporated.

- EXAMINEProduct Blueprint Construction Examination

- STRIP LAYOUTStrip Layout

Design - TRANSLATEMolding

Analysis - MOLDMold

Design - SUPPORTTraining

Support

Expected Benefits

Check out the expected benefits of HANKUK Precision!

-

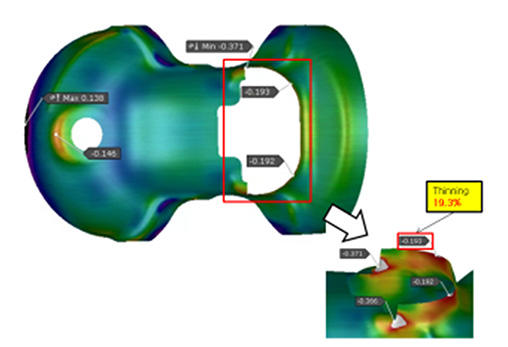

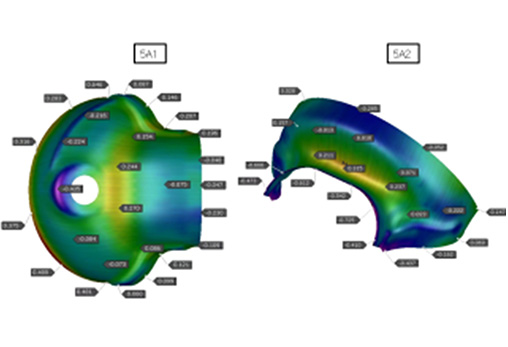

VERIFICATION

Major quality factors such as fracture, thickness reduction, and wrinkles of products can be verified early by using the molding analysis software

-

BLANK SHAPE

Determination of the shape and size of the blank, which is the main factors of the progressive mold

-

MINIMIZATION

Minimization of material costs to customers

-

MOLD TRYOUT

Manufacturing of high-quality molds with short delivery time by modification time and cost reduction of mold tryouts